Phew, what a scorcher. Temperatures have soared with long sunny days and warm nights. Following on from the reasonable levels of rainfall that we have had over the last couple of weeks everything is growing like topsy (see Uncle Tom’s Cabin for this reference to Topsy – interesting).

Due to other commitments I have not been up to Pop’s wood yet this week but instead have been using the time at home to begin to construct a solar log drying kiln. Sounds grander than it is in reality. The idea is very simple and basically comprises a large box with one of the sides covered with glass and positioned facing the sun. Just like in a greenhouse the sun heats up the air in the “kiln” and with a couple of inlets and outlets allows the warm air to circulate around the logs. This warm air picks up the moisture in the recently felled logs and then vents it out gradually drying out the wood. Given the right conditions this should accelerate the seasoning process from in excess of say 12 – 15 months to as short as 3 – 4 weeks. This would allow some of the turkey oak to be sold in the autumn in time for this year’s heating season.

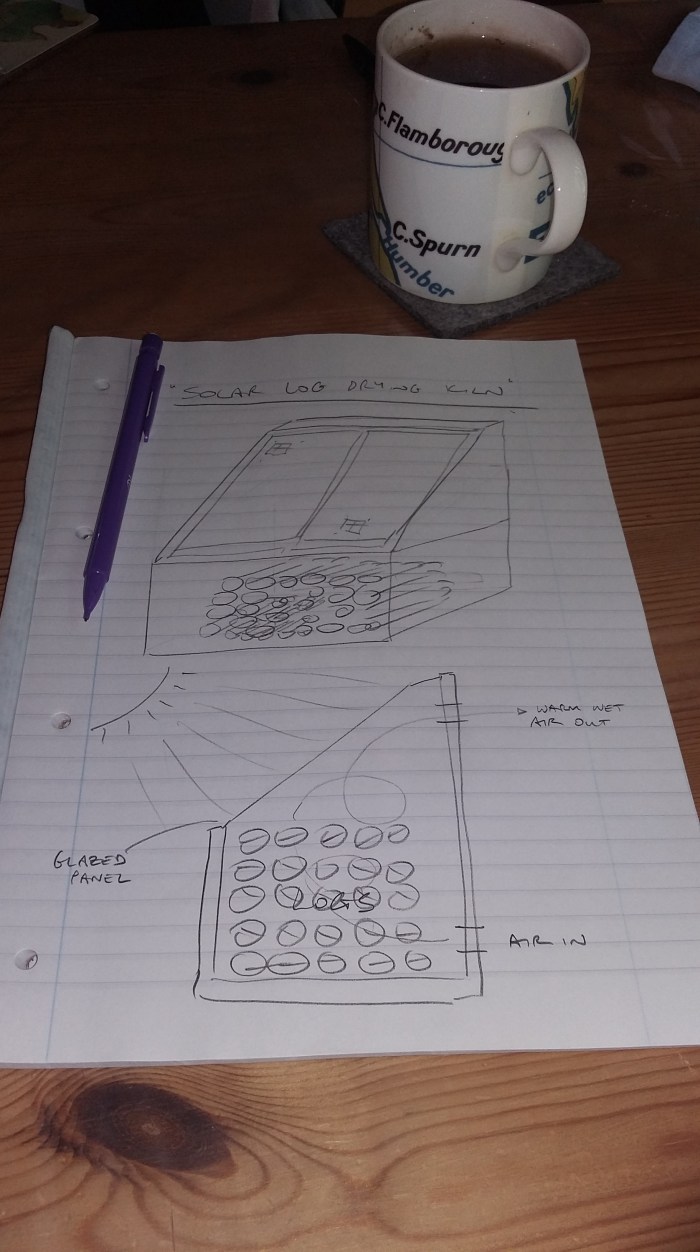

So how do you build one? Look on Youtube of course. Here is my sketch of what I decided to build learning from various previous soar kiln builders.

So having developed a detailed plan I have started the build. Here are a few shots of the work in progress.

It is important that all the heat generated in the kiln goes into heating up the air and not the surrounding woodland. To try and retain the heat in the kiln I have made the walls double skinned and filled the cavity with insulation – rockwool in this instance.

If the kiln works well then it will generate quite a bit of heat in the summer sun and will dry out the logs pretty quickly. It really doesn’t matter how quickly firewood logs are dried out as the objective is simply to lower the moisture content so making the logs more energy efficient when burnt in a stove. The structural integrity of the firewood is of no consequence. However, this approach would be far too fast and fierce for drying out lengths of wood intended for use as timber. Here the drying process needs to be slow ensuring that the wood dries out evenly and free from “shakes”, which are the splits that you see running length ways in some timber. The plan is to see how this kiln works on firewood and then modify for drying out timber later in the year.

More next time………..