Wheat, deer and hazel. Not a firm of solicitors but rather what caught my eye in Pop’s Wood. Well that’s seven weeks or more without rain……… until there was a thunderstorm at tea time today (Friday) and quite a lot of rain fell in a short period. Welcome relief as the temperature had been building throughout the week and had been 25 – 30°C every day.

I presume that the hot dry weather is good for the wheat in the neighbouring field at the top of Pop’s Wood. It looks amazingly golden and is brittle to touch. I guess too little rain and the grain wouldn’t form properly but maybe the wet spring helped to set the seed and now the warm sun is ripening the crop nicely. I love the ages old association that we have with cereal crops and couldn’t resist picking an ear and gently separating the wheat from the chaff.

The grains taste very floury – naturally doh (or dough?) – but they are also surprisingly sweet. I have no idea of the final destination for this particular field of wheat, but it certainly looks very healthy.

What the fully grown crop also reveals is the regular routes created by the herd of deer that frequently pass through and graze within Pop’s Wood.

Now I am no deer stalker but when I spin around 180° it is very easy to make out the path that they follow into the wood.

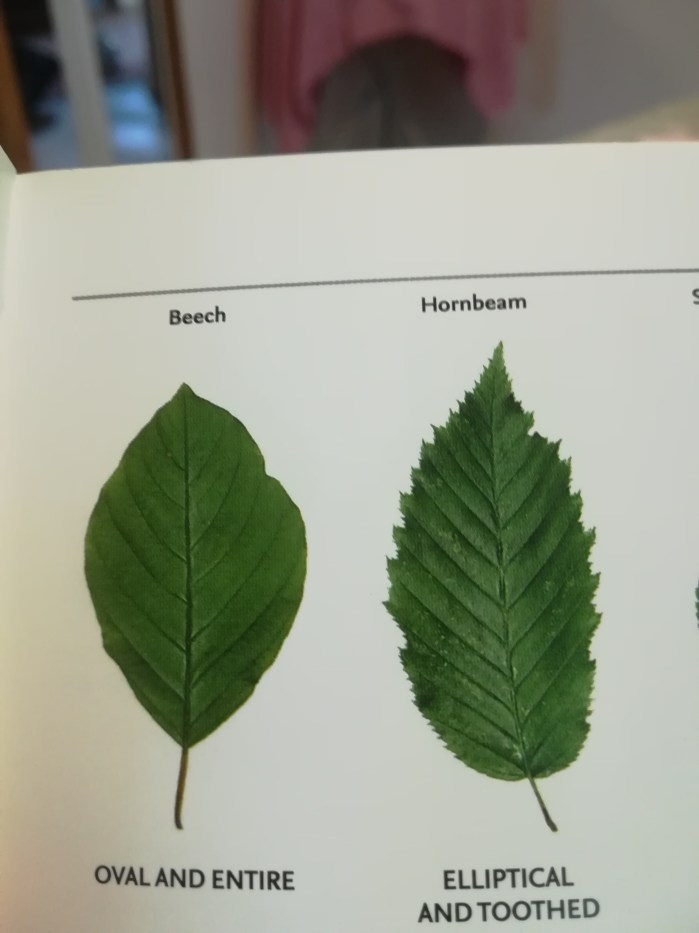

I am about to try making charcoal with the hazel branches that I coppiced back in the autumn/winter of 2016. These logs have been stacked drying out since being cut and so should be fairly well seasoned by now. However I do think that they will still have a higher moisture content than the beech that I am currently using. So the idea is to explore whether in fact they are suitable for charcoal making; how long will it take to complete a burn; and, will the finished charcoal be suitable for use?

If the answers to those questions are positive then that will be a great outlet/purpose to which to put the further coppiced hazel logs. In the autumn I plan to make a start on the first area of wood to be re-established as hazel coppice. There will be a few uses for the thicker felled hazel stems including being split and used as temporary fence posts to support the deer proof netting erected around the new stools. But also having a way of ensuring that all the coppiced wood is put to good use is very important. The first hazel wood charcoal burn will be this next week so I will include any feedback as we go.

More next time………….

I am making good progress with moving the container to the top of the wood. More next time……………………

I am making good progress with moving the container to the top of the wood. More next time……………………